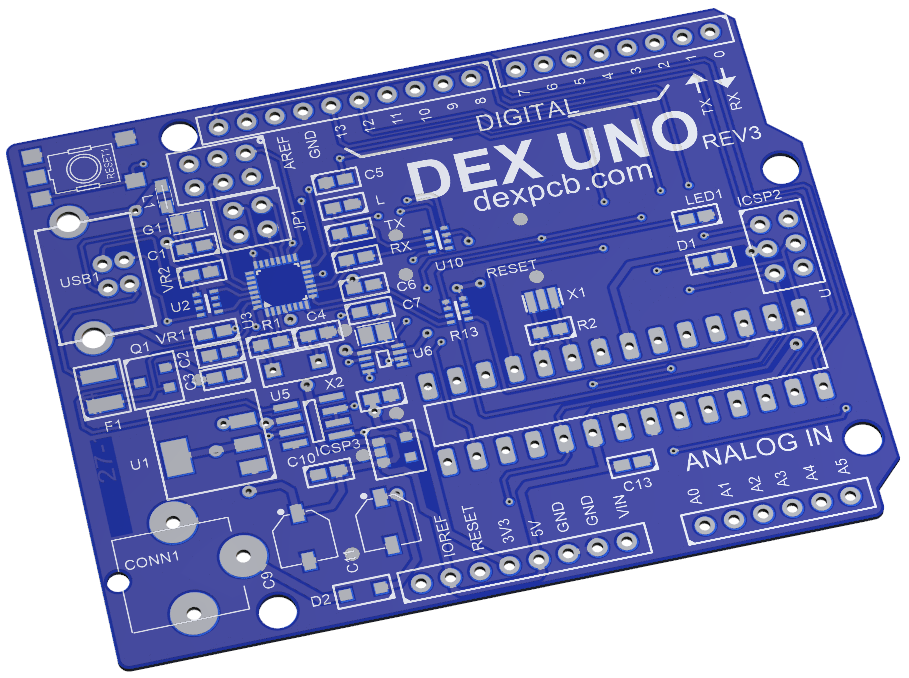

The PCB is the physical manifestation of your design and represents your ultimate goal - To make a PCB.

A Typical PCB with no Parts

The PCB border refers to the outer edge or outline of a printed circuit board (PCB). It plays a significant role in defining the physical dimensions of the PCB and can impact both the manufacturing and functionality of the circuit board.

PCB Holes are openings in a printed circuit board (PCB) that serve various purposes in the design and manufacturing of electronic circuits. They are essential for both functional and mechanical aspects of PCB design.

PCB cutouts are openings or voids created in a printed circuit board (PCB) design to accommodate specific components, features, or mechanical requirements.

PCB layers serve several critical purposes in electronic design and functionality.

Footprints in PCB design are the physical layouts or patterns that define where electronic components will be placed and soldered onto the board. A footprint includes the arrangement of pads, holes (for through-hole components), and outlines that match the specific dimensions of a component. It ensures proper electrical and mechanical connections between the component and the PCB.

PCB nets are the electrical connections that link different components on a printed circuit board (PCB). A net represents a group of pins, pads, or terminals that should be electrically connected together. Nets are essential in defining the signal flow and power distribution within the PCB design, ensuring that components interact correctly based on the schematic.

PCB vias are small, plated holes that create electrical connections between different layers of a multi-layer PCB. They allow signals or power to pass vertically through the board, connecting traces on separate layers.

PCB copper pours are large areas of copper that cover specific sections of a PCB, typically used to create ground planes or power planes. They provide low-resistance paths for electrical signals and help with heat dissipation, electromagnetic interference (EMI) shielding, and voltage stability. Copper pours fill unused spaces on the PCB and are often connected to ground or power nets.

PCB keepout regions are designated areas on a printed circuit board where components, traces, and vias are restricted from being placed. These regions are defined to avoid electrical interference, mechanical conflicts, or to maintain necessary clearances for components, connectors, or mounting holes. Keepout regions help ensure proper functionality, manufacturability, and assembly of the PCB.

PCB split power planes are sections of a single power plane that are divided to carry different voltage levels or power domains within a multi-layer PCB. Each section supplies power to specific components with distinct voltage requirements, while maintaining isolation between them. Split power planes help manage power distribution efficiently and reduce noise or interference between circuits operating at different voltages.

PCB fiducials are small reference markers placed on a printed circuit board to assist automated assembly machines in accurately aligning and positioning components. These markers provide a visual guide for the machine's vision system to calibrate and locate the PCB's orientation during assembly. Fiducials are essential for ensuring precision in placing surface-mount components, especially in high-density or complex designs.

PCB V-cuts are grooves or notches scored into a printed circuit board to partially separate individual boards from a larger panel. These cuts allow multiple boards to be manufactured together and easily snapped apart after assembly. V-cuts are typically used to simplify the production process and reduce handling during mass production. The "V" shape allows the boards to remain connected by a thin layer of material until they are broken apart.

A Printed Circuit Board (PCB) is a flat board made of insulating material that serves as the foundation for connecting electronic components. It mechanically supports and electrically connects various electronic components through conductive pathways, or traces, etched from copper sheets. PCBs are a fundamental part of nearly all electronic devices, from simple gadgets to complex systems like computers and smart-phones.

Key Components of a PCB

•Substrate: The base material, often made of fiberglass or composite epoxy, provides structural support. The most common substrate material is FR-4.

•Copper Layer: A layer of copper is laminated onto the substrate to form conductive traces that connect different components on the PCB.

•Solder Mask: A protective layer applied over the copper traces to prevent short circuits and corrosion. It typically comes in green, but other colors are also available.

•Silkscreen Layer: This layer is used for printing labels, symbols, and other markings on the PCB for identification and assembly purposes.

•Pads: These are small areas where electronic components are soldered onto the PCB. They provide the electrical connection points for components like resistors, capacitors, and integrated circuits.

•Vias: These are small holes that allow electrical connections between different layers of a multilayer PCB. They are crucial for routing signals from one layer to another.

Types of PCBs

•Single-Sided PCBs: These have components mounted on one side and traces on the other. They are simple and cost-effective, commonly used in basic electronic devices.

•Double-Sided PCBs: These have conductive traces on both sides of the board, allowing for more complex designs and a greater number of components. They are connected by vias.

•Multilayer PCBs: These consist of multiple layers of substrate and copper, allowing for very complex circuitry in compact spaces. They are used in advanced applications, such as computers and smart-phones.

•Flexible PCBs: Made from flexible materials, these PCBs can bend and twist, making them suitable for applications where space is limited or in wearable devices.

•Rigid-Flex PCBs: These combine rigid and flexible PCB technology, allowing for intricate designs that can flex in certain areas while remaining rigid in others.

Applications of PCBs

•Consumer Electronics: Used in devices like smart-phones, tablets, televisions, and computers.

•Automotive: Integrated into vehicle systems for control, navigation, and entertainment.

•Medical Devices: Found in diagnostic equipment, monitoring systems, and therapeutic devices.

•Industrial Equipment: Used in machinery control systems and automation.

•Telecommunications: Essential for network equipment, routers, and communication devices.

Manufacturing Process

•Design: Using PCB design software, engineers create the layout, specifying components, traces, and other features.

•Fabrication: The board is manufactured by etching the copper layer to form the desired circuit pattern and applying solder mask and silkscreen layers.

•Assembly: Components are mounted onto the PCB using soldering techniques such as wave soldering or surface-mount technology (SMT).

•Testing: After assembly, the PCBs are tested for functionality and reliability before being integrated into final products.

Advantages of PCBs

•Compact Design: PCBs allow for high-density circuit designs, saving space in electronic devices.

•Cost-Effectiveness: Mass production of PCBs reduces manufacturing costs, making them affordable for a wide range of applications.

•Reliability: PCBs are robust and can withstand environmental factors, leading to longer lifespans for electronic devices.

•Ease of Production: Standardized manufacturing processes streamline production and assembly.

Summary

A PCB is a crucial component in modern electronics, providing the structural and electrical framework for connecting components. Its design and manufacturing processes play a significant role in the functionality, reliability, and performance of electronic devices across various industries.