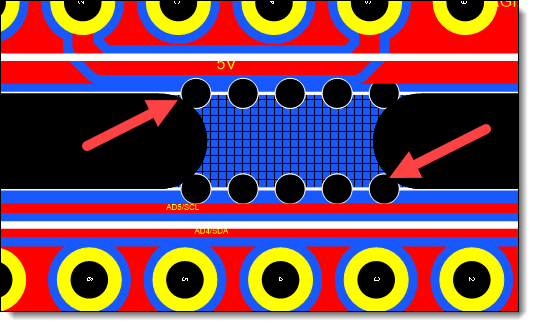

"Mouse bites" in the context of Printed Circuit Boards (PCBs) refer to small, perforated holes that are used to hold multiple PCBs together during the manufacturing process. When PCBs are made, they are often produced in a panelized format for easier assembly. This means multiple PCBs are created as part of a larger panel that can be broken down into individual boards later.

Mouse-bites

When these panels are manufactured, it's often necessary to keep them connected in some way for easier handling and to ensure they all go through the same process at the same time. "Mouse bites" are one of the ways to do this. They're called that because they look like small nibbles a mouse might make.

After the manufacturing process is complete, these 'bites' allow the PCBs to be easily separated from each other by applying a small amount of force, while keeping the individual boards intact and undamaged. This breaking process is also referred to as "depaneling".

Just note that while mouse bites are a common method for de-paneling, there can be some concerns regarding the stress that breaking the panel can cause to the components on the board. Hence, other methods like V-groove or routing are also popular.